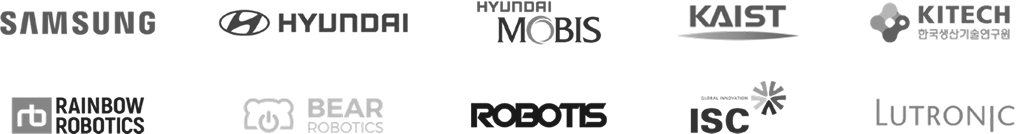

Aluminum

High machinability & lightweight. Ideal for anodizing and post-processing.

Prototypes, Robot Parts, Housings

Superior Thermal Conductivity

Materials

AL6061-T6, AL7075-T6, AL5052

From alloys to plastics,

get instant AI quotes and experience the perfection of our precision machining.

80%

Unmatched Retention

4.9

Average Rating

10K+

Projects Completed

ZERO

Zero Breaches

We help you select the optimal metal or plastic based on your specific needs.

High machinability & lightweight. Ideal for anodizing and post-processing.

Prototypes, Robot Parts, Housings

Superior Thermal Conductivity

Materials

AL6061-T6, AL7075-T6, AL5052

High durability & heat resistance. Perfect for heavy-duty industrial components.

Chemical & Food Industry Parts

Superior Corrosion Resistance

Materials

SUS304, SUS316L

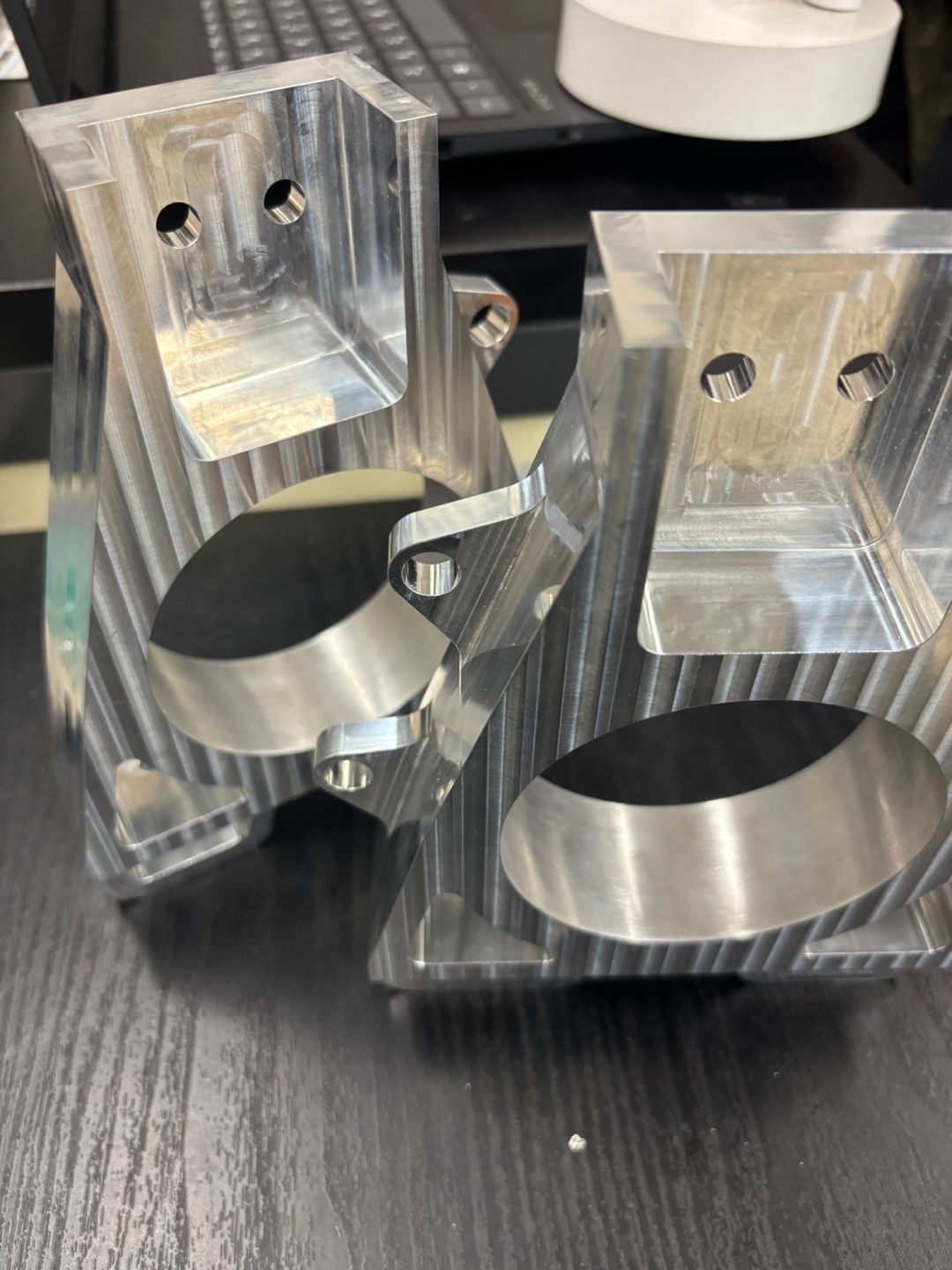

High-strength, high-precision alternatives to 3D printing for functional use.

Jigs, Fixtures, Mechanical Parts

Wear Resistance & Insulation

Materials

ABS, PC, MC Nylon, POM, PEEK

High conductivity and corrosion resistance. Perfect for precision electronic parts.

Electrodes, Heat Sinks, Valves

Aesthetic Golden Finish

Materials

Brass

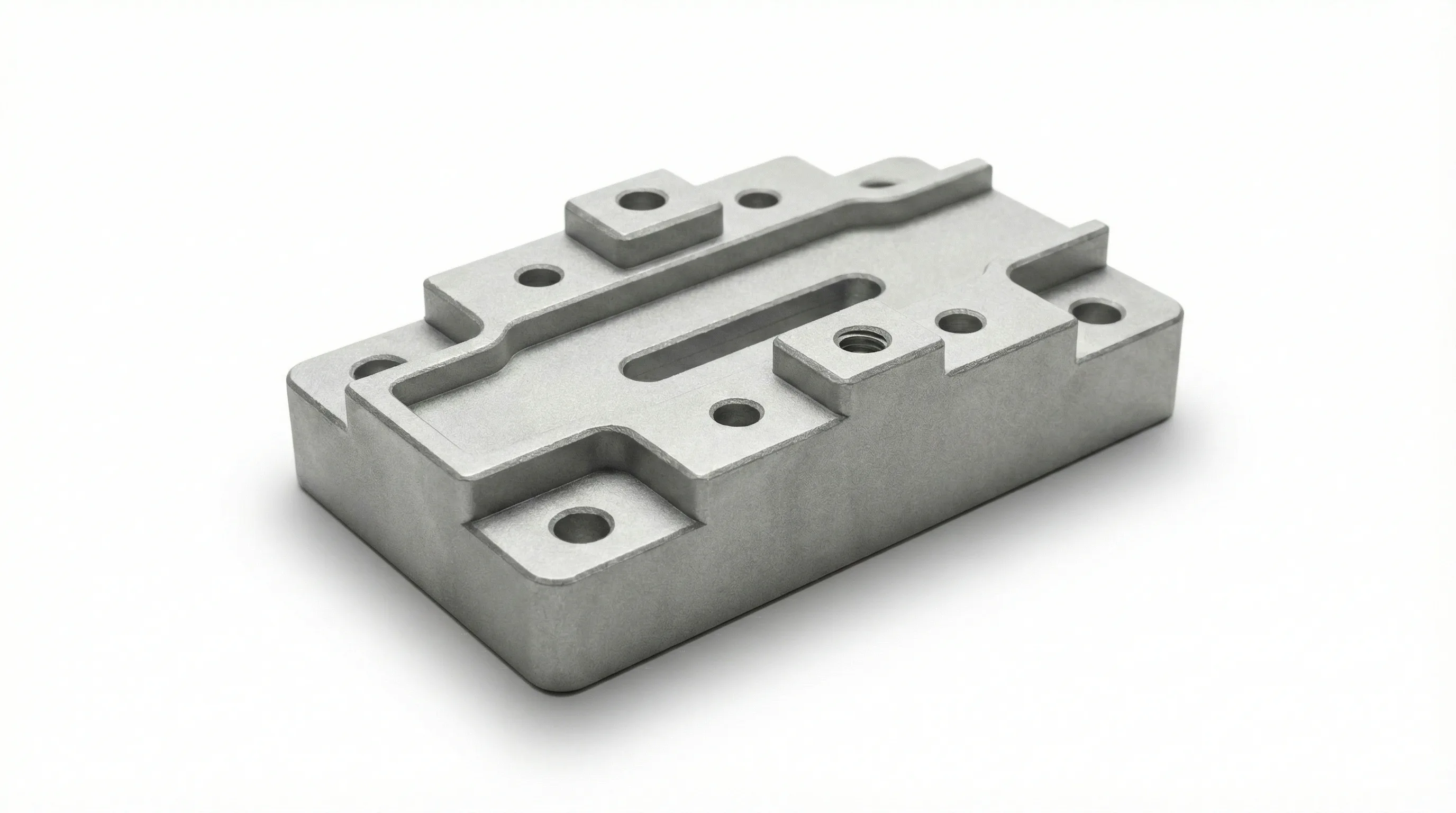

Add the perfect finishing touch to your CNC parts for superior quality.

Removes tool marks with fine abrasives to create a uniform, matte surface finish.

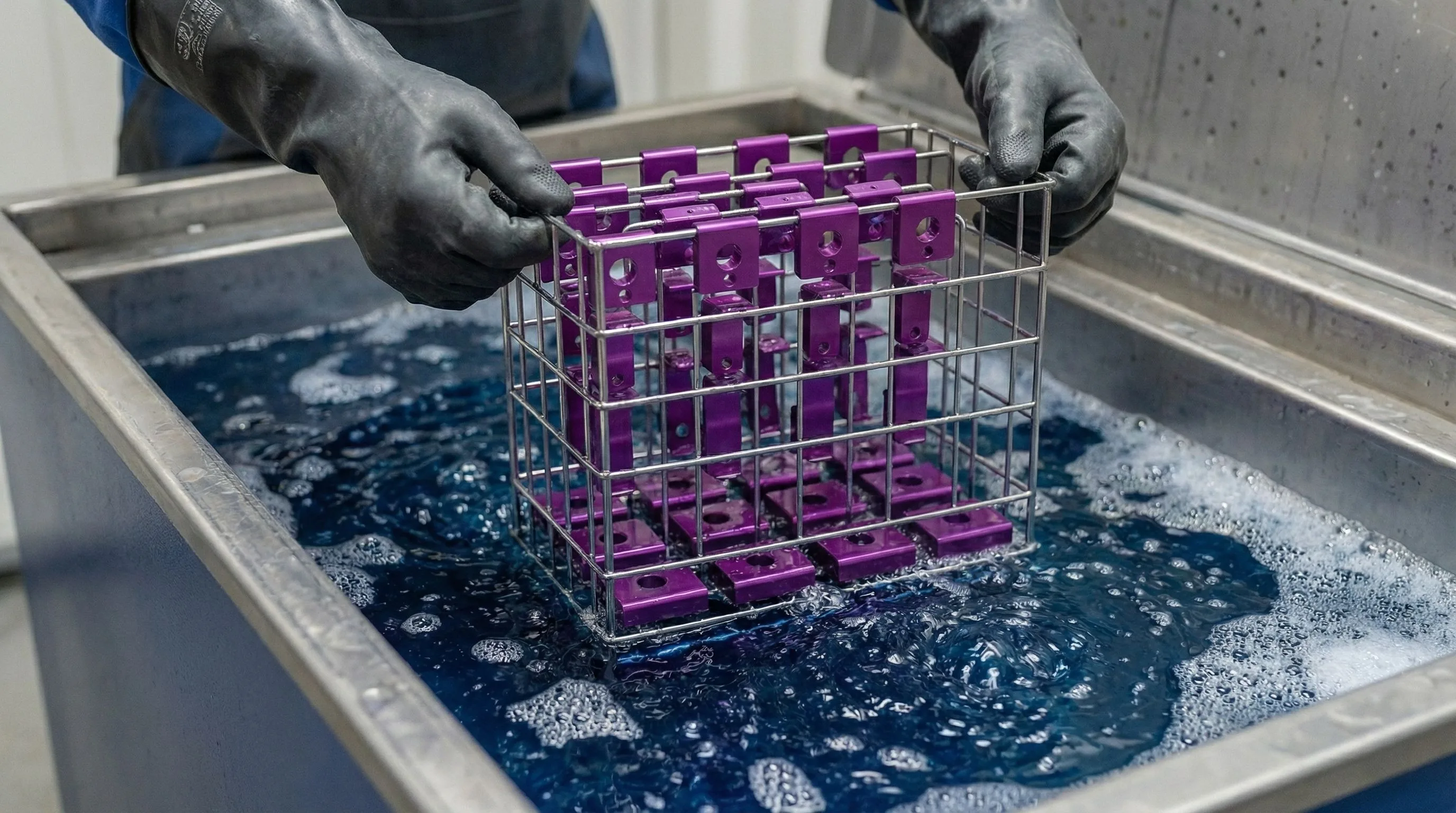

Forms a protective oxide layer on aluminum to prevent corrosion and apply vibrant colors.

Melts dry powder into a heavy-duty, protective color layer with high impact resistance.

Achieve production-grade aesthetics with Pantone color matching, SF coating, and custom gloss finishes.

Let AI handle the complexity. Focus only on your ideas.

Drag and drop STL or STEP files.

Check a 1-second quote and real-time manufacturability (DFM) report.

We manufacture at our own factory or the best-fit partner and deliver via the fastest route.

Transparency

Reliability

We don’t simply connect suppliers. We own the quality.Our engineers manage every step: from DFM to final inspection.

From upload to order in just 5 minutes—AI-driven quotes and DFM analysis eliminate the need for complex emails.

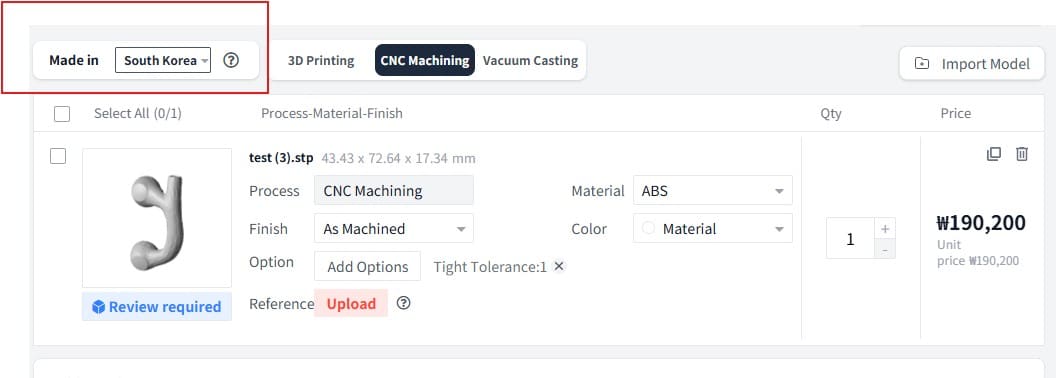

Upload your 3D design file (formats: STL, STP/STEP). Select the correct unit of measurement before uploading.

Seamless Up to 2,000mm

No sectioning

We deliver monolithic machining for large-scale components, preserving structural integrity and design precision.

Large-Scale Machining Capacity: Max 2,000mm

From semiconductor frames and large display jigs to automotive components.

5-Face Machining

Multi-angle precision in a single setup, minimizing tolerance for large parts.

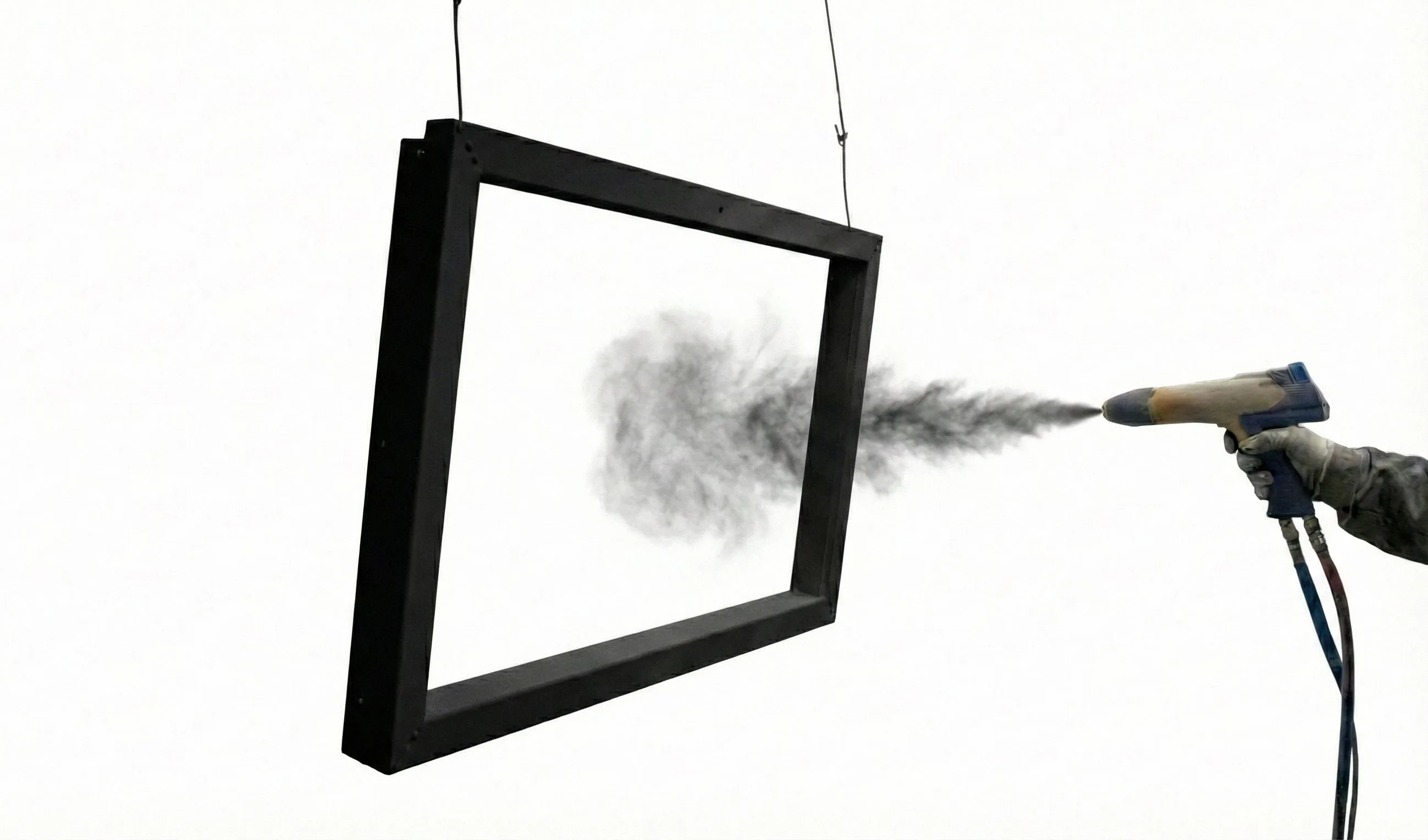

Precision Measurement System

Quality assurance via Large-scale CMM and Laser Trackers.

CAPABILITY

High-Capacity Gantry Machining Center

Extensive machining capabilities—managed with complete quality oversight from start to finish.

Ironclad IP protection via NDAs and strict physical security.

30+ materials, 5-axis, and 2m large-scale CNC solutions.

From 1 unit to mass production with transparent, instant quotes.

Rigorous standards with dedicated PMs and precision QA.

Discover how Creallo delivers high-quality results across diverse industries.

Explore Portfolio합리적인 납기 및 가격에 고품질입니다. 비드블라스트 및 아노다이징 가공 의뢰는 처음인데, 생각보다 잘 나와서 좋습니다. 특히 와이어 EDM 등 특수 가공이 필요한 부분이 있어 별도로 요청드렸는데 깔끔하고 정확하게 작업되어 아주 만족스럽습니다.

처음 CNC 가공을 진행하였기 때문에 걱정도 많았고 지식도 부족해서 실수도 많았지만 친절하게 응대해주시고 좋은 품질에 저렴한 가격으로 빠르게 배송까지 받을 수 있어서 너무 만족했습니다. 다음에도 꼭 CREALLO 에 CNC 가공 맡기고 싶습니다. 감사합니다!!

이전 주문했을 때는 약간의 QC 오류로 일부 재제작이 필요했는데, 이번에는 완벽하게 제작되어 왔습니다. 제 실수로 참조 도면에서 일부 오류가 있었는데, 주문 접수 과정에서 해당 부분에 대해 피드백 요청이 미리 온 점도 매우 만족스러웠습니다. 특히 정밀공차 요청드린 부분이나 타 업체에서는 제작이 어려운 부분까지 잘 제작되어 매우 만족합니다. 제조업에 종사하지 않기에 정확하게는 모르겠지만, 깊은 내측 직각부 키홈홀은 와이어 EDM으로 제작된 것 같은데, 해당 부분을 고려했을 때 합리적인 가격이라고 생각합니다. 소량 생산에서 이 정도 가성비 나오는 업체는 요새는 거의 없는 것 같습니다. 웹 자동견적 시스템만 잘 업데이트 되면 더욱 자주 이용하게 될 것 같습니다.

1-1.Can I get a CNC quote with only 2D drawings?

Laser cutting and sheet metal fabrication can be quoted using only 2D drawings.

However, due to the complexity of part geometry, CNC machining cannot be accurately quoted from 2D drawings alone.

For an accurate quote, please also submit a 3D file in STEP (.stp) format along with your 2D drawing.

1-2.What if my desired CNC material isn’t listed?

Material options vary by country. Change the production location in the quote page to see updated availability.

1-3.Do you offer secondary machining on existing products?

No. We only provide CNC machining for new parts.

1-4.How do you apply tight tolerances?

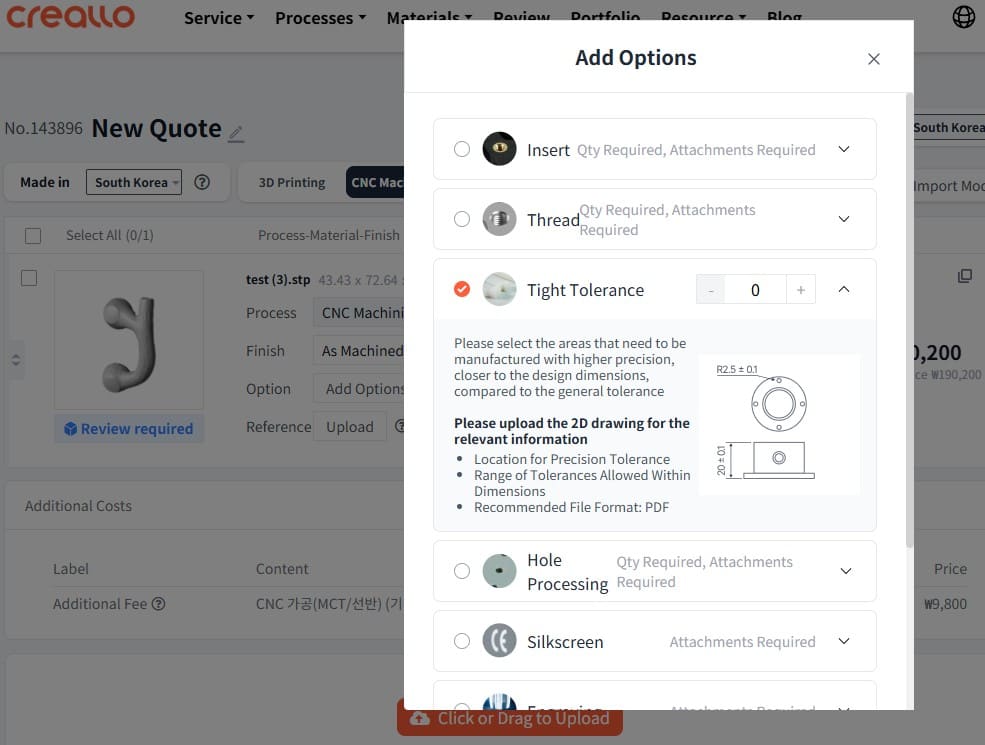

Click Add Options, select Tight Tolerance, and upload a 2D drawing (PDF) that specifies the required tolerances.

Skip the wait. Upload your file for an AI-powered real-time quote and start production today.

Get Instant Quote