Find the answer you need right away in the FAQ.

1-1.Business Hours and Consultation Availability

For inquiries outside of business hours, please leave a 1:1 inquiry and we will respond to them in order.

Weekdays Mon – Fri: 10:00 AM – 06:00 PM (KST, +9:00)

Lunch Break: 12:30 PM – 01:30 PM

1-2.Can I observe the production process on-site?

Yes. You can visit our domestic factory to observe SLA/SLS 3D printing, CNC machining, and post-processing in person.

Please make a reservation in advance via 1:1 inquiry or email us at support@creallo.com.

1-3.Can I get a quote without a 3D model?

A 3D model (STEP, STL, etc.) is required for production.

If you only have 2D drawings (DWG, DXF), we can provide a simplified quote, but actual manufacturing requires a 3D model. We recommend preparing a 3D file before submitting your request.

1-4.What are the minimum order requirements or additional charges?

Creallo has no MOQ (minimum order quantity) – production starts from 1 unit.

However, a minimum order amount applies. If the part cost is lower, the difference will be charged as an additional fee. To reduce additional charges, increase the order quantity or add parts using the same material/color.

Additional costs may vary according to the exchange rate.

ABS-like White Resin: 37,800 KRW

ABS-like Black Resin: 56,600 KRW

ABS-like Brown Resin: 56,600 KRW

Transparent Resin: 37,800 KRW

Nylon: 56,600 KRW

All: 75,500 KRW

All: 105,700 KRW

All: 50,000 KRW

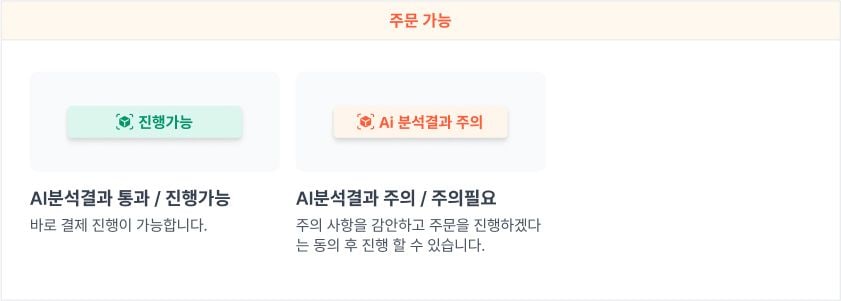

1-5.How should I interpret AI and expert model review results?

A project can proceed only if all model checks return as “Pass/Manufacturable” or “Warning.”

If any other result is included, additional action will be required before production.

AI Result: Pass / Proceed

You can proceed directly to payment.

AI Analysis Result: Warning/Needs Attention

You may continue with the order once you have reviewed the highlighted issues and agreed to proceed with those risks in mind.

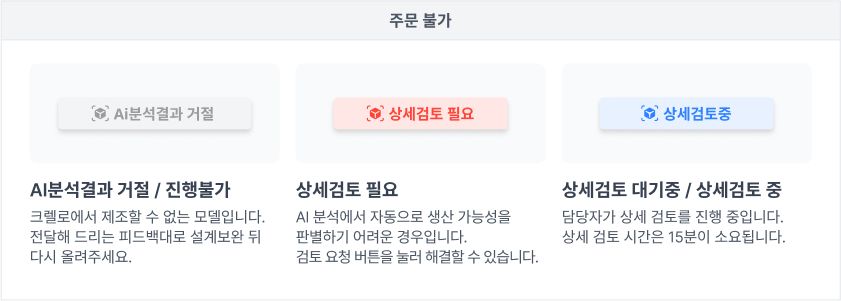

AI Analysis Result: Fail/Cannot Proceed

The model cannot be manufactured by Creallo. Please revise your design based on the feedback provided and re-upload the file.

Detailed review required

When the AI analysis cannot automatically determine manufacturability, the status will show as “Detailed Review Required.” Please click the Final Review Request button in the lower-right corner before payment.

Pending detailed review / Under detailed review

The person in charge is conducting a detailed review. This process usually takes about 15 minutes to 1 day depending on the complexity of the model.

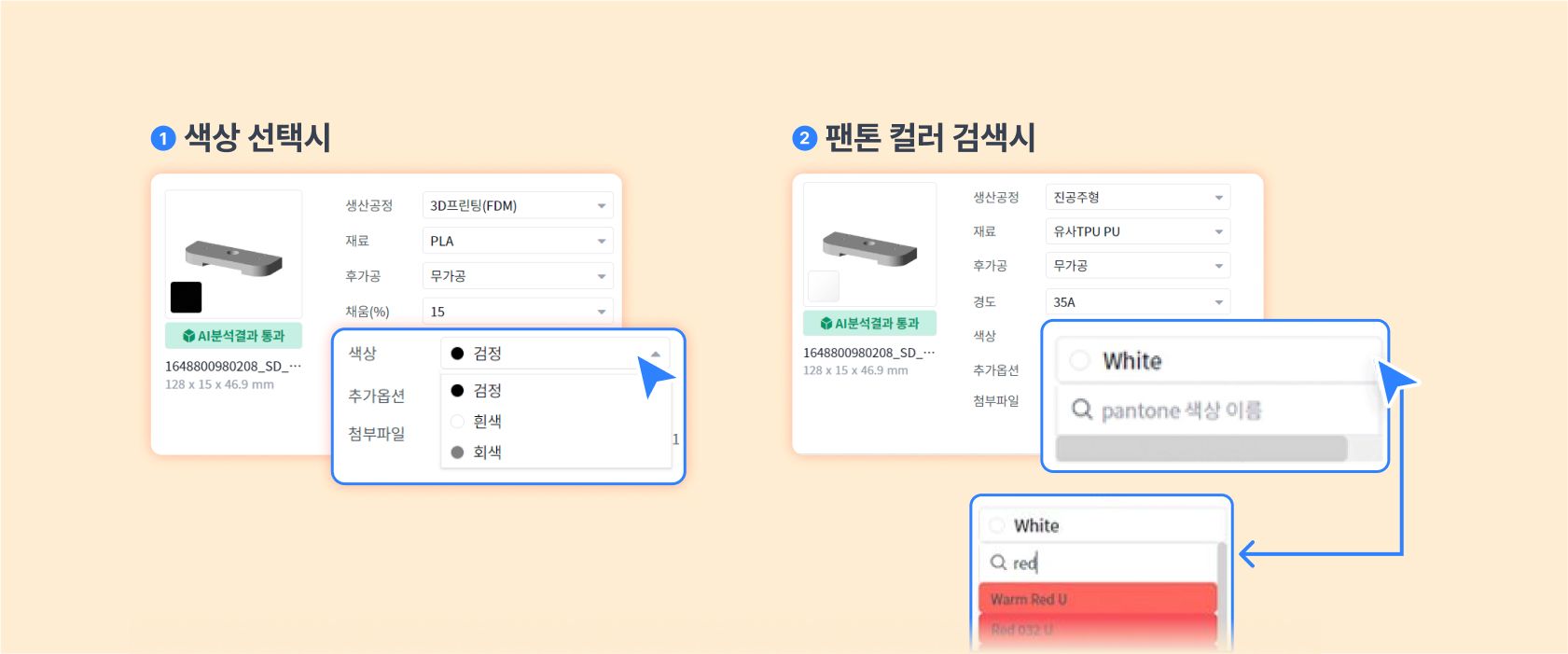

1-6.What painting colors are available? How do I get a painting quote?

[Pantone Color Search Guide]

Use the Creallo Pantone Color Finder to check available colors.

How to use the Pantone color search engine →

Go to Creallo Pantone Color Search Engine →

*Hand-mixed colors may have slight variations.

[Real-time Painting Quote Service Guide]

With the real-time quoting system, you can apply colors, generate a quote, and check lead time instantly.

1-7.What should I do if my part arrives defective or damaged?

Submit details and photos via Manage Order → Inquiry or 1:1 Inquiry. We will review and provide a solution promptly.

[Go to Refund Criteria and Procedures]

1-8.Can I purchase or rent 3D printers and materials from Creallo?

Yes. SLA and SLS 3D printers and materials we operate are available for purchase or long-term rental. Contact support@creallo.com for details.

FDM printers and materials are not supported.