SLS (Selective Laser Sintering) 3D printing builds parts layer by layer by sintering powdered material with a high-powered laser on a print bed.

A high-powered laser precisely scans the powder surface, sintering the targeted areas to form solid layers. After each layer is completed, fresh powder is automatically added, and the process repeats to create highly detailed 3D structures.

✓ Excellent heat, chemical, impact, and wear resistance

✓ No need for support structures

✓ Capable of producing complex geometries

✓ Wide range of color dyeing options

✓ High-strength material options allow for broad application

✓ High build efficiency enables scalable production

✓ Rough surface finish

✓ Post-processing can be challenging

3D Model (STP (STEP), STL)

Material

Finish

Creallo is the first in the Asia-Pacific region to deploy the EOS P3 NEXT system, delivering high-quality production of complex parts and scalable small-batch manufacturing with enhanced flexibility and competitiveness.

Advantages of EOS P3 NEXT:

✓ High-performance and eco-friendly materials available

Supports PA11 and PA12 materials suitable for parts requiring specific properties such as heat resistance, impact strength, and flexibility. Biocompatible materials are also available for applications in medical devices and food-related components.

✓ Reduced total cost

Fast printing speeds and high-density part nesting enable cost-effective small-batch production.

✓ Sustainability and eco-conscious manufacturing

High material reuse rates and flexible custom production help reduce waste and effectively support companies’ ESG strategies and green manufacturing projects.

Innovations Powered by EOS SLS 3D Printing Technology

Breezm's 3D-Printed Eyewear

Consumer Goods

Using advanced 3D scanning and AI data, Breezm mass-produces face-customized eyewear in 70+ styles and 10 colors with SLS 3D printing.

Festo's Bionic Bee Drone

Aerospace

The SLS-printed frame reduced weight from 12g to 3g, boosting flight time and agility without compromising stability.

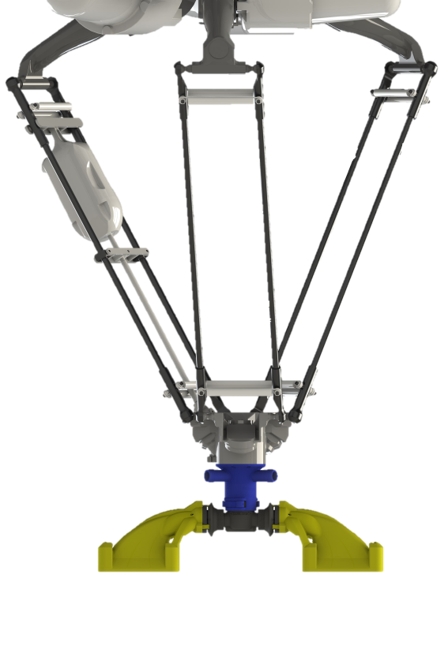

LMD's POS Baking Gripper

Automation

A flexible, rounded SLS printed gripper minimizes collision risk and integrates functions for better space and cost efficiency.

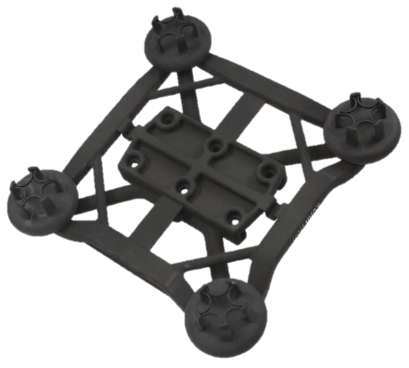

Kuhn-Stoff's Lightweight Gripper

Automation

SLS printing reduced weight by 86%, cut costs by 50%, and shortened lead time from 12 to 3 days for this robotic gripper.

Atlas Copco's Rivet Feeder Bowl

Automotive

With SLS 3D printing, lead time dropped 92%, costs fell 30%, and material waste was reduced to nearly zero.

Anubis 3D's End-of-Arm Tooling

Automation

SLS enabled lightweight tooling with 4× stronger grip, delivered in one week while maintaining robot balance.

Ortoplus's Custom Nylon Splints

Medical

Ortoplus tripled output and improved patient fit using high-precision SLS splints accurate to within ±0.1 mm.

Materials

Creallo Manufacturing Case